Fast and accurate calculations

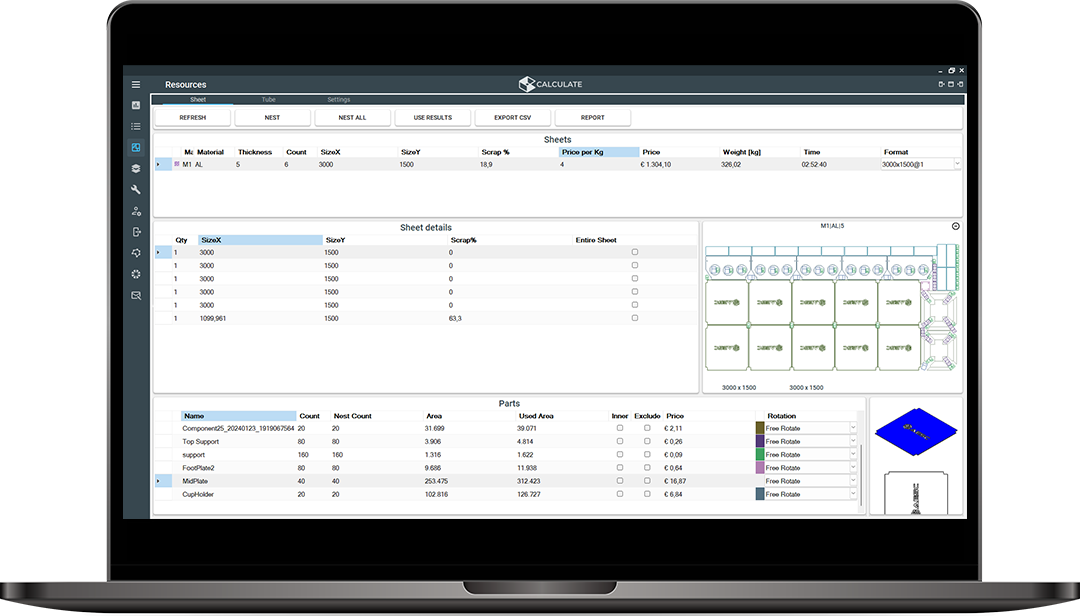

CALCULATE

Make the work preparation of metal, sheet metal parts and tubes faster and easier with Calculate. Our advanced calculation software streamlines the entire process from request to production. The calculation software for metalworking for making accurate price calculations. Extract all data from the geometry of both 2D and 3D drawings, optimize material use and save time with fast and accurate cost calculations. Calculate can be configured entirely according to your own wishes and can be connected to any ERP system. The integration with the SpaceClaim CAD engine makes it possible to make immediate adjustments to the geometry.

Save 93% of your time with efficient work preparation

Making price calculations for production quotes can be time-consuming. Accurate calculations are important for planners to guarantee quality. Calculate reduces the calculation time from 16 hours to 60 minutes. That’s no less than 93% faster! Work preparation becomes easier and more efficient. Calculate works quickly and accurately and saves a lot of manual work. This drastically reduces the chance of errors. Save hours of time in your production planning!

Customers using Calculate

Request a free demonstration

Curious about the possibilities? We would be happy to show you what Calculate can do for you during a demo.

The benefits of Calculate for the metal industry

Efficiency and speed

Reduce the time between request and production

Calculate achieves up to 93% time savings compared to other calculation methods in making cost calculations. Prepare complex assemblies in a fraction of the usual time. Our software offers accuracy and speed that can save you hours of time in the production process.

Simplicity

Simplify work preparation

Automating the work preparation process reduces pressure on the work planners, leaving more time for the production of parts.

Accuracy

Make accurate price calculations

The calculation software uses live prices thanks to a link with your material database. This means that the cost calculations are always up to date.

Recover files quickly

Integration with Spaceclaim CAD-engine

Thanks to SpaceClaim’s CAD engine, Calculate can effortlessly process poorly drawn CAD files itself. Wether they need to be repaired or optimized, our software ensures that the calculation process is not disrupted. SpaceClaim integration also enables automatic geometry and dimension changes, making your workflow even more streamlined.

Less input work

Easily establish calculation rules

The complexity of compositions in the production process is increasing. Establishing calculation rules reduces work input, thereby limiting errors.

Customized implementation

Use of own calculation rules

Calculate can be configured according to your wished with your own calculation rules. Existing rules are easy to adopt and can be implemented in the calculation software. Calculate can also be connected to a wide range of ERP systems.

User friendly

Clear interface

Calculate has an intuitive and user-friendly interface that puts the user first. The software is designed to simplify complex calculations and makes advanced functionalities easy to use by the entire team.

100% production ready

Files are immediately ready for production

The files can be used directly in the production process. Calculate generates 100% workable output files for production including DXF cutting files.

Calculate connects with every system

Calculate connects seamlessly to a wide range of CAM and ERP systems including Libellula, AutoPOL, MKG, Komdex, RidderIQ, BLM software: Adige, Artube, Protube and more. These connections include realtime access to material prices and operating rates, which is essential for accurate quoting and order management.

Simplify your workflow with Calculate

1. Import geometry

Start importing your 2D or 3D CAD effortlessly. Calculate supports a wide range of formats for seamless integration.

2. Recognize parts & activities

Our software intelligently recognizes individual parts and assemblies consisting of sheet metal, tubes and box profiles and prepares them for further processing.

3. Select materials

Choose from your own materials database. Calculate helps select the optimal materials for your project.

4. Calculate material requirements

Efficiently calculate material requirements. Calculate nests sheet, tubes and box profiles.

5. Assign extra activities

Assign extra necessary working steps.

6. Quotation / Export to ERP

Finally, generate detailed and accurate quotes for fast customer lead times or export directly to your ERP system.

Dive deeper into the features of Calculate

Our software contains features that can be used for every aspect of metalworking. From advanced optimization to extensive checks. Calculate contribute to streamlining your production process, improving product quality and reducing waste.

- NImport geometry from almost any CAD file

- NGenerate clean DXF

- NAutomaticly clean parts lists

- NAutomatic recovery of files

- NAutomatic recognition of engraving in STEP and DXF

- NAutomatic engraving in STEP and DXF

- NCountersink hole recognition

Calculate is widely applicable in the metal industry

Our calculation software can be used for various applications in the metalworking industry. Some examples of these applications are:

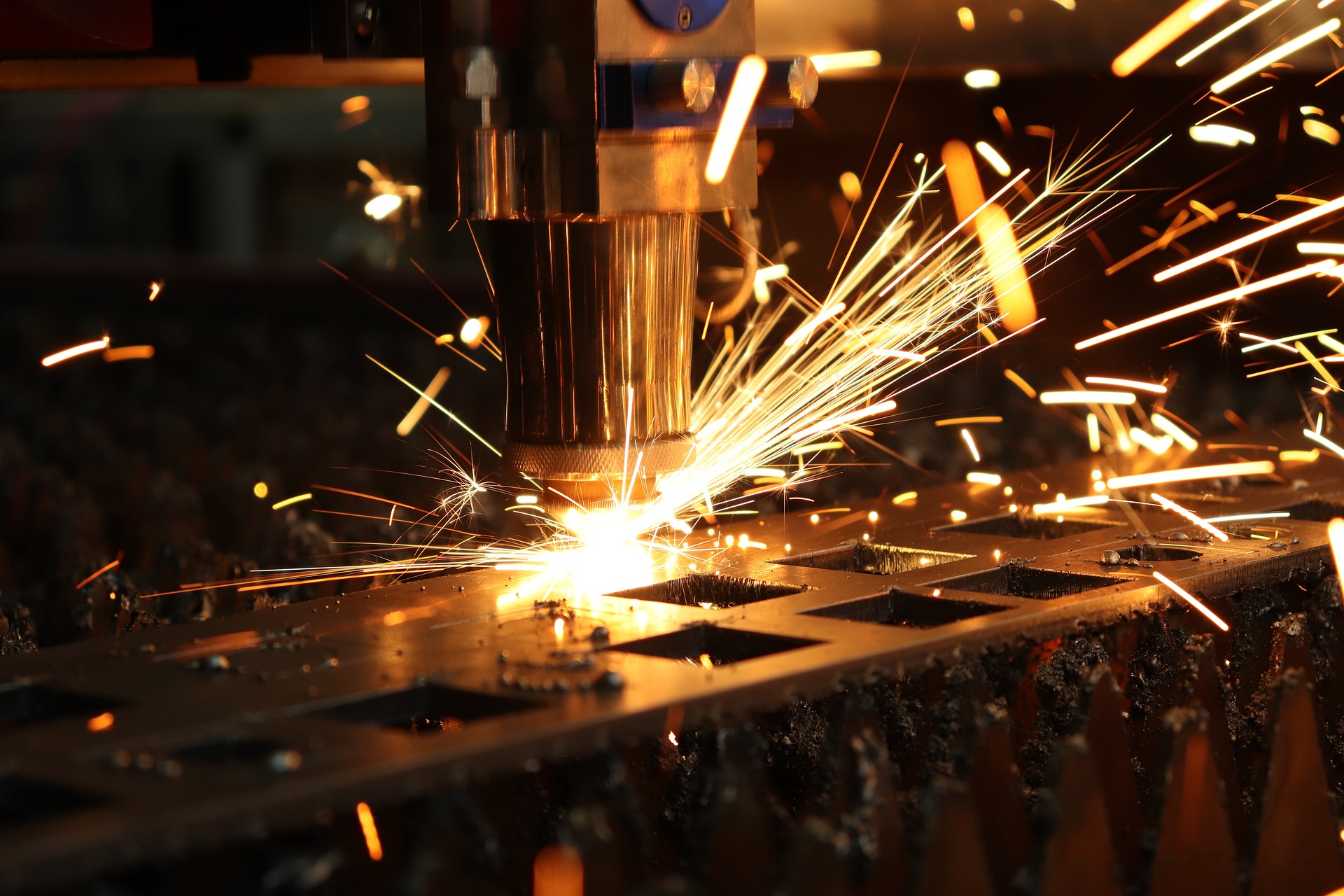

Sheet metal working

Tube laser

Bending

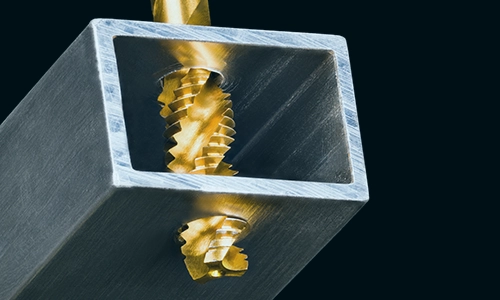

Drilling

Tapping

Surface treatment

Transport

Deburring

Hole countersinking

Purchase parts

and a lot more

How Calculate helped other companies

Questions about Calculate?

Devy will gladly help you.

Devy

CEO